- Curved Lithium Polymer battery

- Fast Charge Polymer Battery

- Flexible Polymer Lithium Battery

- Ultra-thin Polymer Battery

/ Blog / Battery Knowledge /

Hong Kong CityU EES: Flexible lithium-ion battery inspired by human joints

15 Oct, 2021

By hoppt

Research Background

The increasing demand for electronic products has promoted the rapid development of flexible and high-energy-density storage devices in recent years. Flexible lithium ion batteries (LIBs) with high energy density and stable electrochemical performance are considered the most promising battery technology for wearable electronic products. Although the use of thin-film electrodes and polymer-based electrodes dramatically improves the flexibility of LIBs, there are the following problems:

(1) Most flexible batteries are stacked by "negative electrode-separator-positive electrode," and their limited deformability and slippage between multilayer stacks restrict the overall performance of LIBs;

(2) Under some more severe conditions, such as folding, stretching, winding, and complex deformation, it cannot guarantee battery performance;

(3) Part of the design strategy ignores the deformation of the current metal collector.

Therefore, simultaneously achieving its slight bending angle, multiple deformation modes, superior mechanical durability, and high energy density still faces many challenges.

Introduction

Recently, Professor Chunyi Zhi and Dr. Cuiping Han of the City University of Hong Kong published a paper entitled "Human joint inspired structural design for bendable/foldable/stretchable/twistable battery: achieving multiple deformability" on Energy Environ. Sci. This work was inspired by the structure of human joints and designed a kind of flexible LIBs similar to the joint system. Based on this novel design, the prepared, flexible battery can achieve high energy density and be bent or even folded at 180°. At the same time, the structural structure can be changed through different winding methods so that flexible LIBs have rich deformation capabilities, can be applied to more severe and complex deformations (winding and twisting), and can even be stretched, and their deformation capabilities are far beyond previous reports of flexible LIBs. Finite element simulation analysis confirmed that the battery designed in this paper would not undergo irreversible plastic deformation of the current metal collector under various harsh and complex deformations. At the same time, the assembled square unit battery can achieve an energy density of up to 371.9 Wh/L, which is 92.9% of the traditional soft pack battery. In addition, it can maintain stable cycle performance even after more than 200,000 times of dynamic bending and 25,000 times of dynamic distortion.

Further research shows that the assembled cylindrical unit cell can withstand more severe and complex deformations. After more than 100,000 dynamic stretchings, 20,000 twists, and 100,000 bending deformations, it can still achieve a high capacity of more than 88%—retention rate. Therefore, the flexible LIBs proposed in this paper provides a massive prospect for practical applications in wearable electronics.

Research highlights

1) Flexible LIBs, inspired by human joints, can maintain stable cycle performance under bending, twisting, stretching, and winding deformations;

(2) With a square flexible battery, it can achieve an energy density of up to 371.9 Wh/L, which is 92.9% of the traditional soft-pack battery;

(3) Different winding methods can change the shape of the battery stack and give the battery sufficient deformability.

Graphic guide

1. Design of new type of bionic flexible LIBs

Research has shown that, in addition to ensuring high volume energy density and more complex deformation, the structural design must also avoid plastic deformation of the current collector. The finite element simulation shows that the best method of the current collector should be to prevent the current collector from having a small bending radius during the bending process to avoid the plastic deformation and irreversible damage of the current collector.

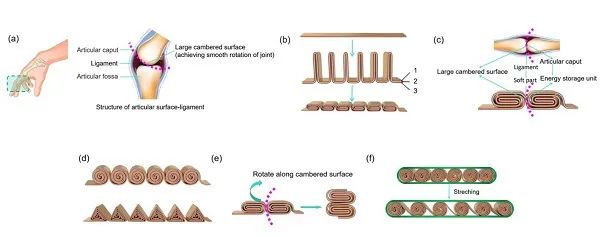

Figure 1a shows the structure of the human joints, in which the cleverly larger curved surface design helps the joints to rotate smoothly. Based on this, Figure 1b shows a typical graphite anode/diaphragm/lithium cobaltate (LCO) anode, which can be wound into a square thick stack structure. At the junction, it consists of two thick rigid stacks and a flexible part. More importantly, the thick stack has a curved surface equivalent to the joint bone cover, which helps buffer pressure and provides the primary capacity of the flexible battery. The elastic part acts as a ligament, connecting thick stacks and providing flexibility (Figure 1c). In addition to winding into a square pile, batteries with cylindrical or triangular cells can also be manufactured by changing the winding method (Figure 1d). For flexible LIBs with square energy storage units, the interconnected segments will roll along the arc-shaped surface of the thick stack during the bending process (Figure 1e), thereby significantly increasing the energy density of the flexible battery. In addition, through elastic polymer encapsulation, flexible LIBs with cylindrical units can achieve stretchable and flexible properties (Figure 1f).

Figure 1 (a) The design of unique ligament connection and curved surface is essential to achieve flexibility; (b) Schematic diagram of flexible battery structure and manufacturing process; (c) bone corresponds to thicker electrode stack, and ligament corresponds to unrolled (D) Flexible battery structure with cylindrical and triangular cells; (e) Stacking schematic diagram of square cells; (f) Stretching deformation of cylindrical cells.

2. Finite element simulation analysis

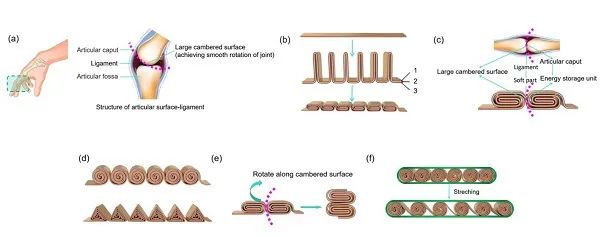

Further use of mechanical simulation analysis confirmed the stability of the flexible battery structure. Figure 2a shows the stress distribution of copper and aluminum foil when bent into a cylinder (180° radian). The results show that the stress of copper and aluminum foil is much lower than their yield strength, indicating that this deformation will not cause plastic deformation. The current metal collector can avoid irreversible damage.

Figure 2b shows the stress distribution when the degree of bending is further increased, and the stress of copper foil and aluminum foil is also less than their corresponding yield strength. Therefore, the structure can withstand folding deformation while maintaining good durability. In addition to bending deformation, the system can achieve a certain degree of distortion (Figure 2c).

For batteries with cylindrical units, due to the inherent characteristics of the circle, it can achieve more severe and complex deformation. Therefore, when the battery is folded to 180o (Figure 2d, e), stretched to about 140% of the original length (Figure 2f), and twisted to 90o (Figure 2g), it can maintain mechanical stability. In addition, when bending + twisting and winding deformation are applied separately, the designed LIBs structure will not cause irreversible plastic deformation of the current metal collector under various severe and complex deformations.

Figure 2 (ac) Finite element simulation results of a square cell under bending, folding, and twisting; (di) Finite element simulation results of a cylindrical cell under bending, folding, stretching, twisting, bending + twisting and winding.

3. Electrochemical performance of flexible LIBs of the square energy storage unit

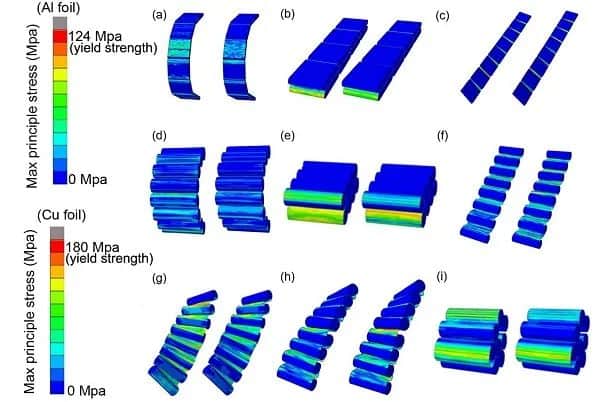

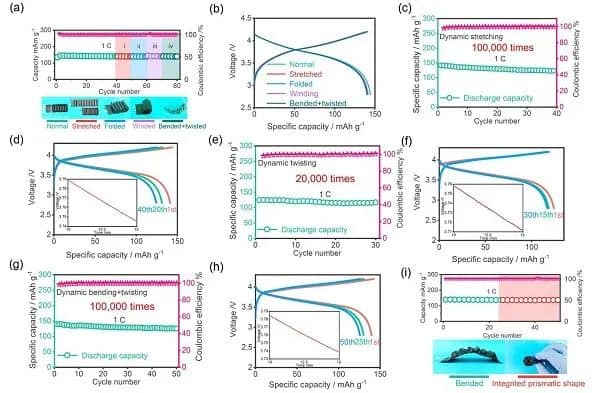

To evaluate the electrochemical performance of the designed flexible battery, LiCoO2 was used as the cathode material to test the discharge capacity and cycle stability. As shown in Figure 3a, the discharge capacity of the battery with square cells is not significantly reduced after the plane is deformed to bend, ring, folded, and twisted at 1 C magnification, which means that the mechanical deformation will not cause the design of the flexible battery to be electrochemically Performance drops. Even after dynamic bending (Figure 3c, d) and dynamic torsion (Figure 3e, f), and after a certain number of cycles, the charging and discharging platform and long-cycle performance have no apparent changes, which means that the internal structure of the battery is well protected.

Figure 3 (a) Charge and discharge test of square unit battery under 1C; (b) Charge and discharge curve under different conditions; (c, d) Under dynamic bending, battery cycle performance and corresponding charge and discharge curve; (e, f) Under dynamic torsion, the cycle performance of the battery and the corresponding charge-discharge curve under different cycles.

4. Electrochemical performance of flexible LIBs of the cylindrical energy storage unit

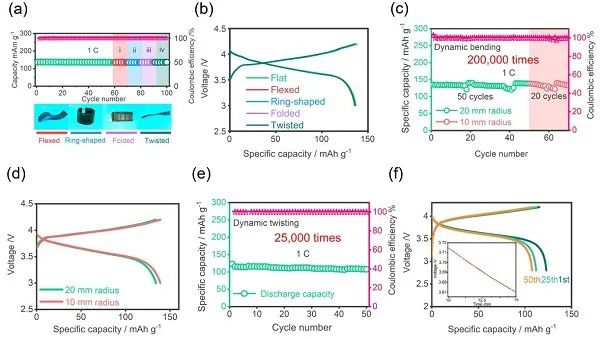

The simulation analysis results show that thanks to the inherent characteristics of the circle, the flexible LIBs with cylindrical elements can withstand more extreme and complex deformations. Therefore, to demonstrate the electrochemical performance of the flexible LIBs of the cylindrical unit, the test was carried out at a rate of 1 C, which showed that when the battery undergoes various deformations, there is almost no change in the electrochemical performance. The deformation will not cause the voltage curve to change (Figure 4a, b).

To further evaluate the cylindrical battery's electrochemical stability and mechanical durability, it subjected the battery to a dynamic automated load test at a rate of 1 C. Research shows that after dynamic stretching (Figure 4c, d), dynamic torsion (Figure 4e, f), and dynamic bending + torsion (Figure 4g, h), the battery charge-discharge cycle performance and the corresponding voltage curve are not affected. Figure 4i shows the performance of a battery with a colorful energy storage unit. The discharge capacity decays from 133.3 mAm g-1 to 129.9 mAh g-1, and the capacity loss per cycle is only 0.04%, indicating that deformation will not affect its cycle stability and discharge capacity.

Figure 4 (a) Charge and discharge cycle test of different configurations of cylindrical cells at 1 C; (b) Corresponding charge and discharge curves of the battery under different conditions; (c, d) Cycle performance and charge of the battery under dynamic tension Discharge curve; (e, f) the cycle performance of the battery under dynamic torsion and the corresponding charge-discharge curve under different cycles; (g, h) the cycle performance of the battery under dynamic bending + torsion and the corresponding charge-discharge curve under different cycles ; (I) Charge and discharge test of prismatic unit batteries with different configurations at 1 C.

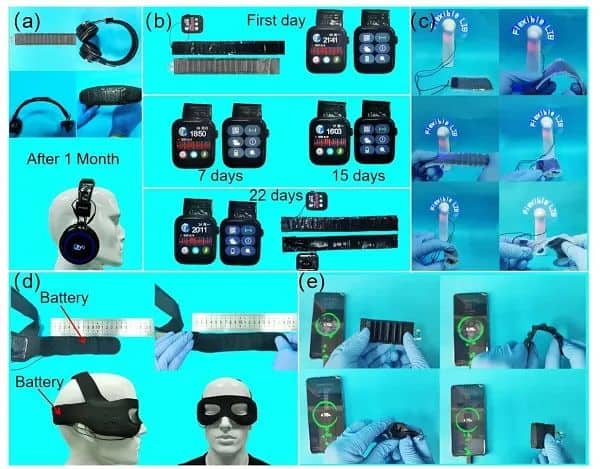

5. Application of flexible and wearable electronic products

To evaluate the application of the developed flexible battery in practice, the author uses full batteries with different types of energy storage units to power some commercial electronic products, such as earphones, smartwatches, mini electric fans, cosmetic instruments, and smart phones. Both are sufficient for everyday use, fully embody the application potential of various flexible and wearable electronic products.

Figure 5 applies the designed battery to earphones, smartwatches, mini electric fans, cosmetic equipment, and smartphones. The flexible battery supplies power for (a) earphones, (b) smartwatches, and (c) mini electric fans; (d) supplies power for cosmetic equipment; (e) under different deformation conditions, the flexible battery supplies power for smartphones.

Summary and outlook

In summary, this article is inspired by the structure of human joints. It proposes a unique design method for manufacturing a flexible battery with high energy density, multiple deformability, and durability. Compared with traditional flexible LIBs, this new design can effectively avoid the plastic deformation of the current metal collector. At the same time, the curved surfaces reserved at both ends of the energy storage unit designed in this paper can effectively relieve the local stress of the interconnected components. In addition, different winding methods can change the shape of the stack, giving the battery sufficient deformability. The flexible battery exhibits excellent cycle stability and mechanical durability thanks to the novel design and has extensive application prospects in various flexible and wearable electronic products.

Literature link

Human joint-inspired structural design for bendable/foldable/stretchable/twistable battery: achieving multiple deformability. (Energy Environ. Sci., 2021, DOI: 10.1039/D1EE00480H)